Over the years, there has been much discussion around the suitability – or otherwise – of polycarbonate (often called by the Lexan brand name) or acrylic (often called plexiglass) for light sport and recreational aircraft windscreens. Of course, as with anything aviation, there are no simple answers as to which material is best. There are pros and cons either way.

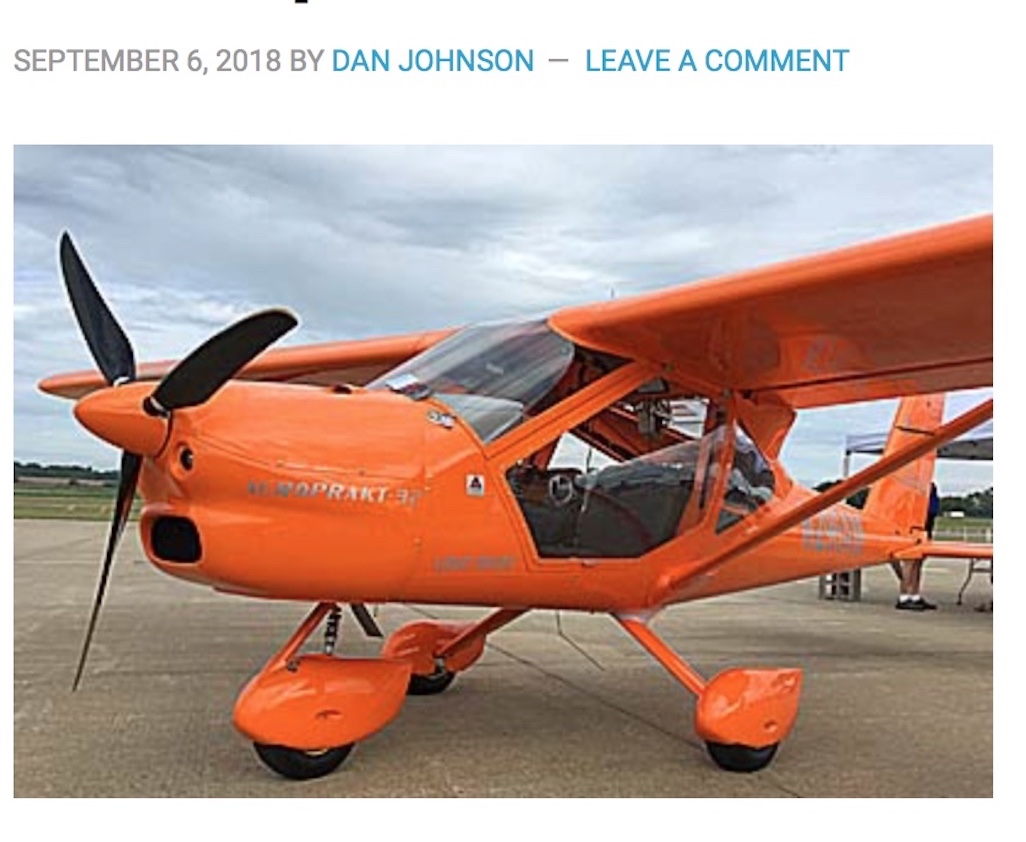

Aeroprakt now offers screens using either type of material – 2mm flat sheet polycarbonate, with UV protection and a scratch resistant coating, which is shaped during installation; or 3mm acrylic pre-shaped to fit. Both types of screen do the job and should last many hundreds if not thousands of hours in service. However, there are potential drawbacks and provisos to the installation and maintenance of each type of screen which, if not followed properly can lead to damage, cracking or at worst shattering of the screen.

Arguments in favour of polycarbonate include:

– it is almost indestructible, even in thin gauges; in fact it is a major component of bullet proof glass!

– by any definition, polycarbonate sheet is very flexible and can be formed cold into even fairly complex curves;

– generally, polycarbonate tolerates drill holes and is more ‘workable’ than acrylic.

The downsides of polycarbonate:

– the main drawback to polycarbonate sheet is its susceptibility to damage from gasoline exposure, even small drips can start to destroy the material and lead to cracks, deformation and the characteristic ‘bubbles’ which seem to be inside the sheet, particularly where it is shaped and under stress. The edges of polycarbonate sheet are notably susceptible to this kind of damage, often resulting in edge cracking;

– some other types of chemicals, typically those used in cleaning products (eg ammonia) also cause similar damage to polycarbonate sheet;

– polycarbonate will slowly discolour due to UV light. However, UV coatings can delay this process and it can take at least 10-15 years to occur, especially if the aircraft is kept in a hangar when not in use.

In favour of acrylic screens:

– generally more scratch resistant than polycarbonate sheet, although scratch-resistant coatings on polycarbonate have improved a lot over the last 10 years or so;

– all but the worst scratches on acrylic can usually be polished out;

– acrylic is optically clearer than polycarbonate, with much less distortion, even around curves;

– generally, acrylic screens will tolerate a wider range of chemicals, including gasoline, without serious damage.

The downsides of acrylic screens:

– acrylic is much more brittle than polycarbonate sheet. As a result, more care is needed when installing to ensure the screen doesn’t shatter just as you install that last rivet!

– acrylic needs a wider margin around screw and rivet holes to ensure expansion does not cause cracking through chafing or expansion stress – if badly installed, an acrylic screen can crack due to the hot sun warming a cool screen with not enough clearance around the rivets;

– at least one bird strike on a Foxbat screen ‘bounced’ off a polycarbonate screen; it’s likely an acrylic screen would have shattered. However, a couple of other bird strikes have shattered polycarbonate screens.

Ultimately, the choice is yours. However, Foxbat Australia has taken the view that the thicker acrylic screen offers enough overall benefit to standardise it on all A22 and A32 aircraft supplied new in Australia. These advantages include its better resistance to fuel, less susceptibility to edge cracking and, last but not least, reduced noise in the cabin. The 3mm screen is also available as a retro-fit item on both models of aircraft – it’s relatively quicker to install than the 2mm flat screen but you do need a jig (which can be loaned).

There’s a great Kitplanes Magazine article here, which goes into more detail about both types of material:- http://bit.ly/2NNJ7eE

Way back in late January 2020, Simon and Jane, who live near Cairns in north Queensland, ordered a new red Foxbat. Remember those days? We were dealing with summer temperatures, bushfires and had no inkling of what was to come.

Way back in late January 2020, Simon and Jane, who live near Cairns in north Queensland, ordered a new red Foxbat. Remember those days? We were dealing with summer temperatures, bushfires and had no inkling of what was to come.

Off I go

Off I go

My return flight was with

My return flight was with  Melbourne, addressed me by name! A nice touch – now I know what it feels like (well, almost) to have your own private airliner!

Melbourne, addressed me by name! A nice touch – now I know what it feels like (well, almost) to have your own private airliner! My partner Louise met me in the car park and we started our journey home in the car. I was stunned as we exited the multi-storey park to see a vista of completely empty long-term car parks, as far as the eye could see. The mothballed aircraft were shocking enough but somehow the hectares and hectares of empty long-term car parks really hit home. And this is just Melbourne airport – this picture is repeated many times over around the world.

My partner Louise met me in the car park and we started our journey home in the car. I was stunned as we exited the multi-storey park to see a vista of completely empty long-term car parks, as far as the eye could see. The mothballed aircraft were shocking enough but somehow the hectares and hectares of empty long-term car parks really hit home. And this is just Melbourne airport – this picture is repeated many times over around the world.

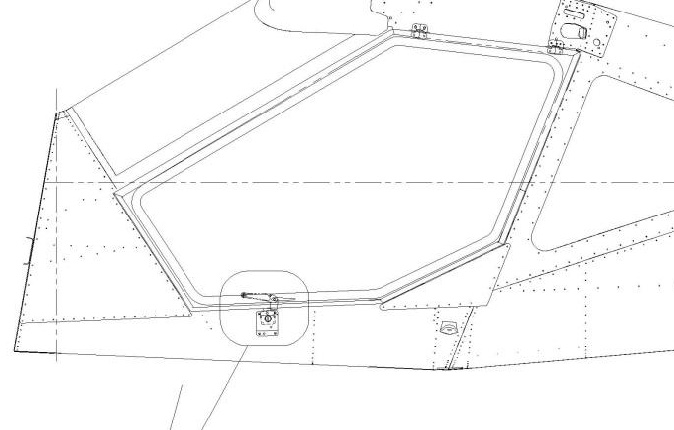

First among these is a new windscreen design, using moulded 3mm acrylic instead of the flex-to-shape 2mm flat polycarbonate sheet. The acrylic windscreen is more rigid than the original design, which has served us well for over 20 years. The main benefit is noise reduction in the cabin, particularly noticeable in the A32 Vixxen, which is already a relatively quiet aircraft. There are a couple of minor downsides – the acrylic screen needs special jigs both for original installation and when a replacement screen is fitted; it’s also more expensive than the original, flat sheet design. All new A22LS Foxbats/Kelpies and A32 Vixxens built for Australia after 01 January 2020 will be fitted as standard with the new type of screen.

First among these is a new windscreen design, using moulded 3mm acrylic instead of the flex-to-shape 2mm flat polycarbonate sheet. The acrylic windscreen is more rigid than the original design, which has served us well for over 20 years. The main benefit is noise reduction in the cabin, particularly noticeable in the A32 Vixxen, which is already a relatively quiet aircraft. There are a couple of minor downsides – the acrylic screen needs special jigs both for original installation and when a replacement screen is fitted; it’s also more expensive than the original, flat sheet design. All new A22LS Foxbats/Kelpies and A32 Vixxens built for Australia after 01 January 2020 will be fitted as standard with the new type of screen. Next, the A22LS Foxbat will now have as standard the so-called ‘Kelpie’ metal luggage bay with side door. We have sold 20 of the Kelpie variant since we introduced it around 2 years ago and in addition, most Foxbat buyers have opted for the Kelpie bay over the previously ‘standard’ canvas luggage container. The main reason for this is probably that the metal luggage bay is rated at 30 kgs maximum as opposed to the canvas container at 20 kgs. The contents of the container remain accessible in flight and a hard cover is included if in-flight access is not required. There is a small basic weight penalty but as the A22LS is already one of the lightest (and strongest) LSAs on the Australian market, you will still be able to carry over 200 kgs of people and bags, even after filling full with fuel.

Next, the A22LS Foxbat will now have as standard the so-called ‘Kelpie’ metal luggage bay with side door. We have sold 20 of the Kelpie variant since we introduced it around 2 years ago and in addition, most Foxbat buyers have opted for the Kelpie bay over the previously ‘standard’ canvas luggage container. The main reason for this is probably that the metal luggage bay is rated at 30 kgs maximum as opposed to the canvas container at 20 kgs. The contents of the container remain accessible in flight and a hard cover is included if in-flight access is not required. There is a small basic weight penalty but as the A22LS is already one of the lightest (and strongest) LSAs on the Australian market, you will still be able to carry over 200 kgs of people and bags, even after filling full with fuel. We have offered a variety of VHF radios over the years, including the popular German Filser/Funkwerk OLED radio. However, after extensive experience with

We have offered a variety of VHF radios over the years, including the popular German Filser/Funkwerk OLED radio. However, after extensive experience with

When the factory announced the 600kgs gross weight A22LS (Light Sport) version, I wanted to differentiate it from the original lighter weight A22L aircraft. From a distance of a few metres, the A22L and A22LS look pretty much identical, and the signature yellow paint continued, so one obvious way was to change the logo. After discussions with a local designer, I decided to drop the red star and the ‘Foxbat’ script and use only the fox head symbol. In fact, this was subliminally sharpened up to make it look more aggressive and, in a distant gesture to the red star, I changed the colours to red and black.

When the factory announced the 600kgs gross weight A22LS (Light Sport) version, I wanted to differentiate it from the original lighter weight A22L aircraft. From a distance of a few metres, the A22L and A22LS look pretty much identical, and the signature yellow paint continued, so one obvious way was to change the logo. After discussions with a local designer, I decided to drop the red star and the ‘Foxbat’ script and use only the fox head symbol. In fact, this was subliminally sharpened up to make it look more aggressive and, in a distant gesture to the red star, I changed the colours to red and black. This new ‘red’ logo was applied to the first few A22LS aircraft – until someone ordered a red one, and the red fox head on the tail just didn’t look right! At the same time, I experienced a couple of misunderstandings about the colour of the registration numbers/letters on the fuselage sides. These are required to be of sufficient contrast to make them easily distinguishable, so I had been using black letters or numerals. All OK on yellow & white aeroplanes but almost invisible on red and blue ones. The designer came to the rescue and we agreed on silver letters and numerals, with a black shadow – which made them easy to see on all aircraft colours. To co-ordinate with the registration colours, I changed the fox head logo on the aircraft to black, white and silver.

This new ‘red’ logo was applied to the first few A22LS aircraft – until someone ordered a red one, and the red fox head on the tail just didn’t look right! At the same time, I experienced a couple of misunderstandings about the colour of the registration numbers/letters on the fuselage sides. These are required to be of sufficient contrast to make them easily distinguishable, so I had been using black letters or numerals. All OK on yellow & white aeroplanes but almost invisible on red and blue ones. The designer came to the rescue and we agreed on silver letters and numerals, with a black shadow – which made them easy to see on all aircraft colours. To co-ordinate with the registration colours, I changed the fox head logo on the aircraft to black, white and silver. In mid-2015 the factory announced the new, fast cruising A32. Many people were happy for this to still be called a Foxbat but, clearly, this was quite a different aeroplane – both to look at and to fly. After much agonising, I finally decided to go with’ Vixxen’ – again, more aggressive, with the extra ‘x’ added to make it a bit more memorable. And so the logo received yet another make over, hopefully to align it with the name. The silver elements were changed for black and the eyes were changed to red, for some eye-candy appeal.

In mid-2015 the factory announced the new, fast cruising A32. Many people were happy for this to still be called a Foxbat but, clearly, this was quite a different aeroplane – both to look at and to fly. After much agonising, I finally decided to go with’ Vixxen’ – again, more aggressive, with the extra ‘x’ added to make it a bit more memorable. And so the logo received yet another make over, hopefully to align it with the name. The silver elements were changed for black and the eyes were changed to red, for some eye-candy appeal. Finally, about 18 months ago, the factory agreed to our suggestions to build an aircraft aimed at appealing to Australia outback landowners and pilots. We added a heavy-duty metal luggage bay with a side door, fat tyres with mud guards, a siren, a UHF radio and a bigger climb prop as well as a couple of other additions. But what to call this aircraft? We decided to be a bit more adventurous than ‘Foxbat Farmer’ and the like. In the end, our sales and service support partners – Cleveland Bay Aviation in Townsville – came up with ‘Kelpie’. This name has a bit more going for it than ‘Dingo’ or ‘Wombat’, suggesting hard work and ruggedness, developed for Australian conditions. And so the latest in a line of logos was born – a bit whimsical but a a bit of fun too. Maybe it’s a combination of the original fox head and a touch of Scooby Doo, ‘well friendly’ as my grandson would say.

Finally, about 18 months ago, the factory agreed to our suggestions to build an aircraft aimed at appealing to Australia outback landowners and pilots. We added a heavy-duty metal luggage bay with a side door, fat tyres with mud guards, a siren, a UHF radio and a bigger climb prop as well as a couple of other additions. But what to call this aircraft? We decided to be a bit more adventurous than ‘Foxbat Farmer’ and the like. In the end, our sales and service support partners – Cleveland Bay Aviation in Townsville – came up with ‘Kelpie’. This name has a bit more going for it than ‘Dingo’ or ‘Wombat’, suggesting hard work and ruggedness, developed for Australian conditions. And so the latest in a line of logos was born – a bit whimsical but a a bit of fun too. Maybe it’s a combination of the original fox head and a touch of Scooby Doo, ‘well friendly’ as my grandson would say.