On what basis do you record your times for scheduled services on your Rotax engine? Engine running hours – start to stop? Starting to taxi to stopping – wheels turning to wheels stopping? Flight time via an air switch – wheels off to wheels on the runway?

On what basis do you record your times for scheduled services on your Rotax engine? Engine running hours – start to stop? Starting to taxi to stopping – wheels turning to wheels stopping? Flight time via an air switch – wheels off to wheels on the runway?

At bigger and/or busier airfields there could easily be a big cumulative difference between engine start/stop and wheels off to wheels on the runway – as much a 25% or more by some LAME accounts. So what is the correct procedure for recording times to determine scheduled maintenance on your Rotax engine? The answer, it seems, has been about as clear as year-old engine oil!

The initial response from the Rotax service department to my query was that maintenance must be carried out based on engine running time as recorded by ‘an electronic engine hours timer’ – ie start-up to shut-down. This is different to some of the statements in their maintenance manuals and certainly not the way most flight schools and clubs record time for engine servicing; they usually use take-off to landing times for overhaul.

Please note:

What follows has now been superseded by the following: all Rotax engine scheduled maintenance times are currently based on engine running times – ie from start up to shut down. Therefore, for maintenance purposes, record engine running times accordingly. Also check to ensure that the airframe manufacturer aligns their mandatory maintenance schedules with the engine maintenance requirements. Most of them do – including Aeroprakt.

Please also see my updated blog post on scheduled maintenance times: https://foxbatpilot.com/2017/04/12/rotax-engines-4-scheduled-maintenance-update/

When questioned a little more, Rotax finally clarified that their engine scheduled maintenance times comply with standard FAA (and CASA) practice – that is, take-off to landing time, ideally measured with an air-switch hours meter. I now have this in writing (by email) from them, so if you or your engineer need written confirmation, let me know.

So, repeating, for the sake of avoiding all doubt – record your engine scheduled maintenance times from take-off to landing. Maybe even fit an air-switch-operated hours counter if you need to. In the long run, this can save you quite a lot when it comes to servicing, likely well more than the cost of fitting an air-switch.

PS – Don’t forget: if you are late with a service – eg 55 hours instead of 50, the next service is still due at 100 hours, not 105. Read the Rotax manuals!

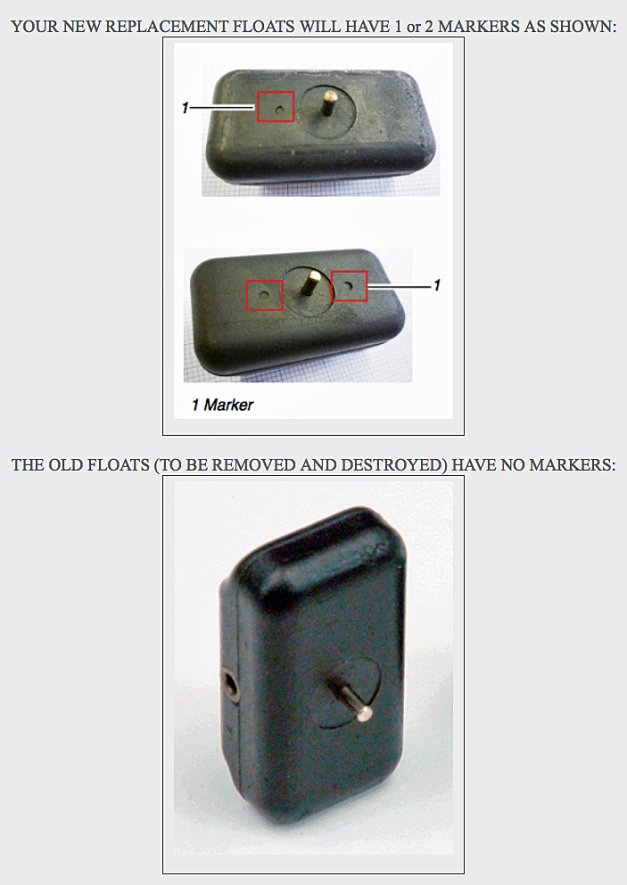

At last Rotax has issued a final service bulletin covering replacement carburettor floats. For those not fully up to speed on this, Rotax has had a problem with ‘permeable’ carburettor floats on most recent 912 series engines. Basically any faulty floats absorb fuel and sink to the bottom of the float chamber, causing rough running and potentially overflowing fuel. Floats on affected engines had to be checked every 25 hours and if needed, replaced.

At last Rotax has issued a final service bulletin covering replacement carburettor floats. For those not fully up to speed on this, Rotax has had a problem with ‘permeable’ carburettor floats on most recent 912 series engines. Basically any faulty floats absorb fuel and sink to the bottom of the float chamber, causing rough running and potentially overflowing fuel. Floats on affected engines had to be checked every 25 hours and if needed, replaced.

On what basis do you record your times for scheduled services on your Rotax engine? Engine running hours – start to stop? Starting to taxi to stopping – wheels turning to wheels stopping? Flight time via an air switch – wheels off to wheels on the runway?

On what basis do you record your times for scheduled services on your Rotax engine? Engine running hours – start to stop? Starting to taxi to stopping – wheels turning to wheels stopping? Flight time via an air switch – wheels off to wheels on the runway?