First, a bit of background

All aircraft have ailerons for controlling bank angles and turns, and many have flaps for lowering the stall speed (and the nose) when landing. One of the many reasons for the superb flight handling characteristics of the A22 Foxbat and A32 Vixxen aircraft is the use of combined ailerons and flaps, colloquially known as ‘flaperons’. I have always found it curious that although their primary use is as ailerons, these control surfaces are not called ‘aileraps’…

The A22 and A32 flaperons are ingeniously designed to give great low-speed control – they are huge when compared with lesser aircraft ailerons – and at the same time maintaining that low speed control when they are lowered as flaps for landing. On A22 and A32 aircraft the flaperons are what are called ‘slotted’ – a term used to describe the flow of air in the gap between the wing and control surface, allowing the airflow to ‘stick’ to the top surface of the flaperon and thus reduce stall speed.

At higher speeds, in the cruise, these big surfaces mean the controls firm up nicely, so you’re not continually having to make corrections to maintain straight and level flight. It’s a bit like the way the steering in modern cars firms up at higher speeds to improve stability.

The A22 and A32 aircraft flaperons have four hinge points, equally spaced along the underside of the control surface. Three of these hinges consist of pins, which are a press-fit into brackets on the flaperon itself, and a bearing mounted in a bracket attached to the wing structure, through which the pins are located to provide a hinge. The hinge pins on the flaperons point inwards towards the fuselage, so to remove the flaperon, you have slide it outwards, towards the wing tip.

The fourth, innermost, hinge is a press-fit bolt attached to a flaperon bracket, secured with a washer, castle nut and split pin. The flaperon is held in place lengthwise by this bolt and cannot move outwards on its hinges and become detached. In fact, the wing tip would also stop the flaperon moving outwards and coming off its hinges, although if this happened, there would be other much more serious problems with the wing!

To remove the flaperon, you have to disconnect the universal joint where the control rods/cables connect and remove the castle nut etc from the inboard hinge. The flaperon then has to be ‘folded’ under the wing and moved outwards off its hinges.

So, how do you ruin the hinge?

Many of the pins used in the A22 and A32 aircraft have holes drilled in the ends to accept a safety pin. Those used on the flaperons are the same and often the hole can be seen when conducting a pre-flight inspection. As described above, the flaperon cannot come off its hinges unless some catastrophic failure of the wing has already occurred – such as in an air-to-air collision.

During flight, all airframes flex slightly – including those of the A22 and A32. This means that the wing and flaperon are moving in relation to each other, albeit by tiny amounts, during every flight. As a result, it is important that the hinge pins are free to move in their bearings.

Yet many people feel an irresistible urge to insert safety pins and even washers in a mistaken belief this will somehow improve the security of the flaperon. In fact, it actually does the reverse.

How?

There are two ways that using safety pins and washers in the flaperon hinges will destroy them:

First, by stopping the hinges moving freely, undue forces are exerted on the pin and although very tightly push-fitted into the flaperon bracket – these pins will work loose. If they fall out – it has been reported! – the integrity of the flaperon will be compromised, leading to potentially catastrophic consequences.

Second, use of washers and split pins can and does provoke rust and corrosion on the pin. Eventually corrosion causes the pin to seize in the bearing and as a result, loosen the push fit pin and the integrity of the flaperon will again be compromised.

Do not add washers or safety pins to the flaperon hinge pins – they are not needed. The flaperon cannot come off its hinges and adding washers or split pins will actually decrease the safety of the aircraft.

The maintenance manual requires regular checking and lubrication of these hinges to ensure a long and trouble free life. Believe me, replacement of a badly corroded hinge and supporting bracket is no simple matter – by that, read EXPENSIVE!

You have been warned!

Way back in late January 2020, Simon and Jane, who live near Cairns in north Queensland, ordered a new red Foxbat. Remember those days? We were dealing with summer temperatures, bushfires and had no inkling of what was to come.

Way back in late January 2020, Simon and Jane, who live near Cairns in north Queensland, ordered a new red Foxbat. Remember those days? We were dealing with summer temperatures, bushfires and had no inkling of what was to come.

Off I go

Off I go

My return flight was with

My return flight was with  Melbourne, addressed me by name! A nice touch – now I know what it feels like (well, almost) to have your own private airliner!

Melbourne, addressed me by name! A nice touch – now I know what it feels like (well, almost) to have your own private airliner! My partner Louise met me in the car park and we started our journey home in the car. I was stunned as we exited the multi-storey park to see a vista of completely empty long-term car parks, as far as the eye could see. The mothballed aircraft were shocking enough but somehow the hectares and hectares of empty long-term car parks really hit home. And this is just Melbourne airport – this picture is repeated many times over around the world.

My partner Louise met me in the car park and we started our journey home in the car. I was stunned as we exited the multi-storey park to see a vista of completely empty long-term car parks, as far as the eye could see. The mothballed aircraft were shocking enough but somehow the hectares and hectares of empty long-term car parks really hit home. And this is just Melbourne airport – this picture is repeated many times over around the world.

It is with a degree of sadness I cannot possibly describe, that I mourn the passing of Ido Segev in an aviation accident last Wednesday, 19th February. Ido worked with me at Foxbat Australia for over 3 years and, for the last 18 months or so, we were joint directors of AeroEdge Australia.

It is with a degree of sadness I cannot possibly describe, that I mourn the passing of Ido Segev in an aviation accident last Wednesday, 19th February. Ido worked with me at Foxbat Australia for over 3 years and, for the last 18 months or so, we were joint directors of AeroEdge Australia.

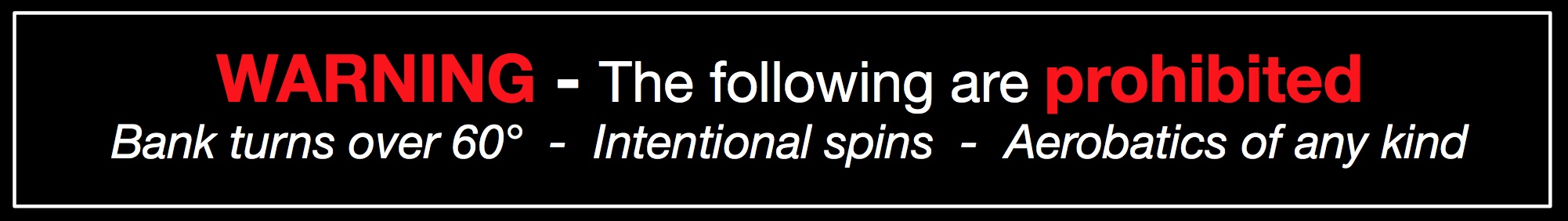

Remember that if the angle of bank exceeds 60 degrees or pitch exceeds 45 degrees from the horizontal, you are already outside of the allowable flight envelope of all LSA aircraft and therefore considered to be conducting ‘aerobatics’ under CASA’s definition.

Remember that if the angle of bank exceeds 60 degrees or pitch exceeds 45 degrees from the horizontal, you are already outside of the allowable flight envelope of all LSA aircraft and therefore considered to be conducting ‘aerobatics’ under CASA’s definition. Here’s an extract from FAA AC 61-67 “Stall Spin Awareness Training”:

Here’s an extract from FAA AC 61-67 “Stall Spin Awareness Training”:

First among these is a new windscreen design, using moulded 3mm acrylic instead of the flex-to-shape 2mm flat polycarbonate sheet. The acrylic windscreen is more rigid than the original design, which has served us well for over 20 years. The main benefit is noise reduction in the cabin, particularly noticeable in the A32 Vixxen, which is already a relatively quiet aircraft. There are a couple of minor downsides – the acrylic screen needs special jigs both for original installation and when a replacement screen is fitted; it’s also more expensive than the original, flat sheet design. All new A22LS Foxbats/Kelpies and A32 Vixxens built for Australia after 01 January 2020 will be fitted as standard with the new type of screen.

First among these is a new windscreen design, using moulded 3mm acrylic instead of the flex-to-shape 2mm flat polycarbonate sheet. The acrylic windscreen is more rigid than the original design, which has served us well for over 20 years. The main benefit is noise reduction in the cabin, particularly noticeable in the A32 Vixxen, which is already a relatively quiet aircraft. There are a couple of minor downsides – the acrylic screen needs special jigs both for original installation and when a replacement screen is fitted; it’s also more expensive than the original, flat sheet design. All new A22LS Foxbats/Kelpies and A32 Vixxens built for Australia after 01 January 2020 will be fitted as standard with the new type of screen. Next, the A22LS Foxbat will now have as standard the so-called ‘Kelpie’ metal luggage bay with side door. We have sold 20 of the Kelpie variant since we introduced it around 2 years ago and in addition, most Foxbat buyers have opted for the Kelpie bay over the previously ‘standard’ canvas luggage container. The main reason for this is probably that the metal luggage bay is rated at 30 kgs maximum as opposed to the canvas container at 20 kgs. The contents of the container remain accessible in flight and a hard cover is included if in-flight access is not required. There is a small basic weight penalty but as the A22LS is already one of the lightest (and strongest) LSAs on the Australian market, you will still be able to carry over 200 kgs of people and bags, even after filling full with fuel.

Next, the A22LS Foxbat will now have as standard the so-called ‘Kelpie’ metal luggage bay with side door. We have sold 20 of the Kelpie variant since we introduced it around 2 years ago and in addition, most Foxbat buyers have opted for the Kelpie bay over the previously ‘standard’ canvas luggage container. The main reason for this is probably that the metal luggage bay is rated at 30 kgs maximum as opposed to the canvas container at 20 kgs. The contents of the container remain accessible in flight and a hard cover is included if in-flight access is not required. There is a small basic weight penalty but as the A22LS is already one of the lightest (and strongest) LSAs on the Australian market, you will still be able to carry over 200 kgs of people and bags, even after filling full with fuel. We have offered a variety of VHF radios over the years, including the popular German Filser/Funkwerk OLED radio. However, after extensive experience with

We have offered a variety of VHF radios over the years, including the popular German Filser/Funkwerk OLED radio. However, after extensive experience with