Sherwood Scout

A couple of years ago I visited the UK Light Aircraft Company (TLAC) factory in Norfolk to look at the single-seat tail-dragger Sherwood KUB aircraft. At the time I noted the high degree of engineering professionalism at the factory and very nearly decided to become the Australian dealer for the KUB. However, when we worked out prices, the A$ vs UK£ exchange rate put an end to my plans. I believed that the retail price for the KUB – great little aeroplane though it is – would not attract many buyers.

Sherwood KUB

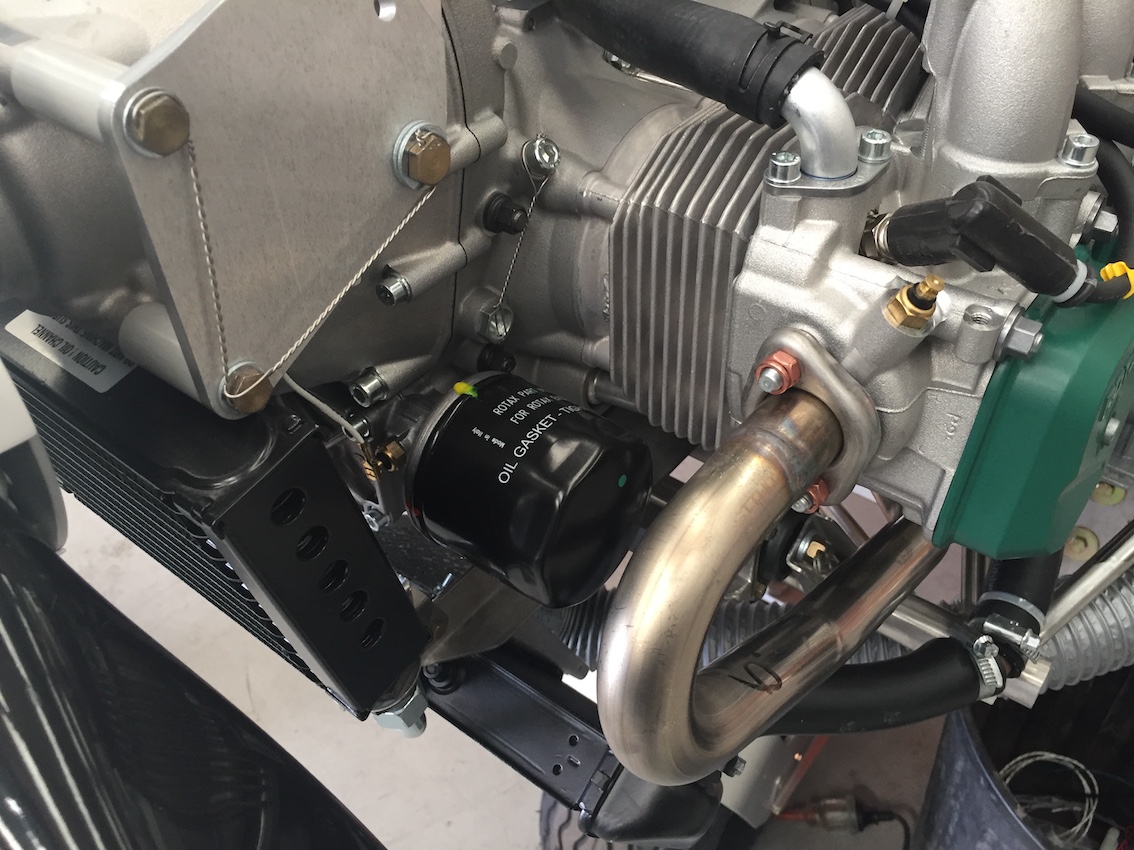

While I was at the factory, I also looked at the Sherwood Scout, a 2-seat high wing Rotax 912ULS powered tail dragger. This aircraft, if you go back far enough, has its history in the Kitfox, although now seriously re-engineered to be stronger and fly (much) better than the older design. Apart from the excellent standard of engineering in the manufacture of this aircraft, it is almost unique both in being covered with UV-proof Oratex and having a (very) easy folding wing, allowing it to be stored in about 25% of the space needed for a fixed wing aircraft.

The aircraft is not the proverbial ‘tube & sailcloth’ aircraft but has a welded 4130 tube fuselage with aluminium spars and wooden ribs. With the Rotax 912ULS/100hp engine, its performance figures are very attractive too. As well as the easy folding wing, add side-by-side seating, a good weight carrying capability, a genuine 95 knots TAS and you have the makings of an excellent bush plane – some might say it would eat Big Cats for breakfast! You can even swap between nose dragging and tail dragging in a better of minutes…

I am an avid subscriber to ByDanJohnson’s Blog – his is one of the top websites covering Light Sport and Recreational aircraft worldwide. And just the other day, one of his contributors, the well-known Dave Unwin, published a flight review of the Scout. Once again, my interest was piqued…

Apart from commenting on the ‘very honest’ flying characteristics – ie very good! – the reviewer also reminded me of the easy folding wing option, making the aircraft much easier to store. Here’s his summary:

“I honestly feel that TLAC has got a winner here! Obviously care needs to be taken with the weight and balance of the lightest version, but with a typical useful load in excess of 517 pounds [235 kgs] the larger Scout [vs KUB] is a very practical machine, with good numbers for speed, range and endurance, and the ability to carry a good load into and out of rather short strips. The folding wings are a big plus, while the ability to reconfigure from a nosewheel to a tailwheel quickly and easily could also be very useful. I liked it, a lot.“

You can read the full article here: Review of the Sherwood Scout

What do you think?

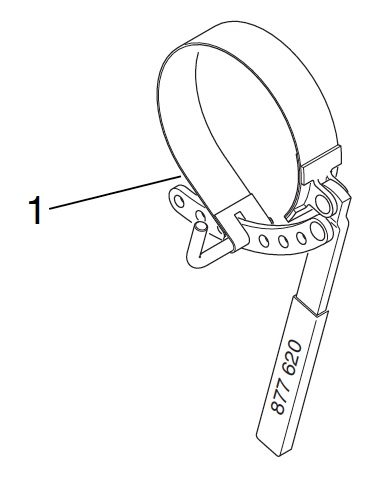

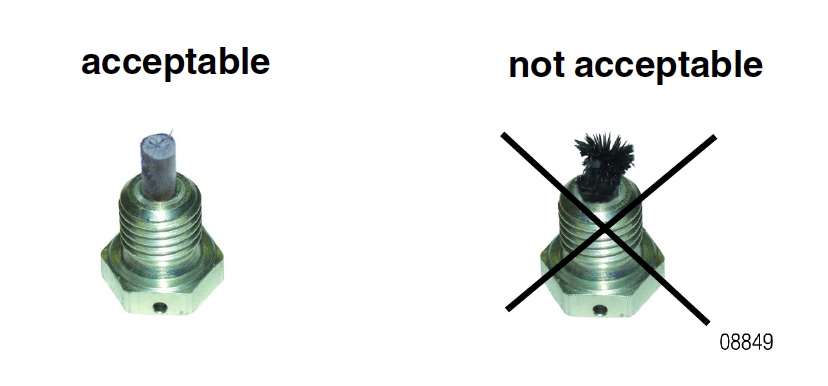

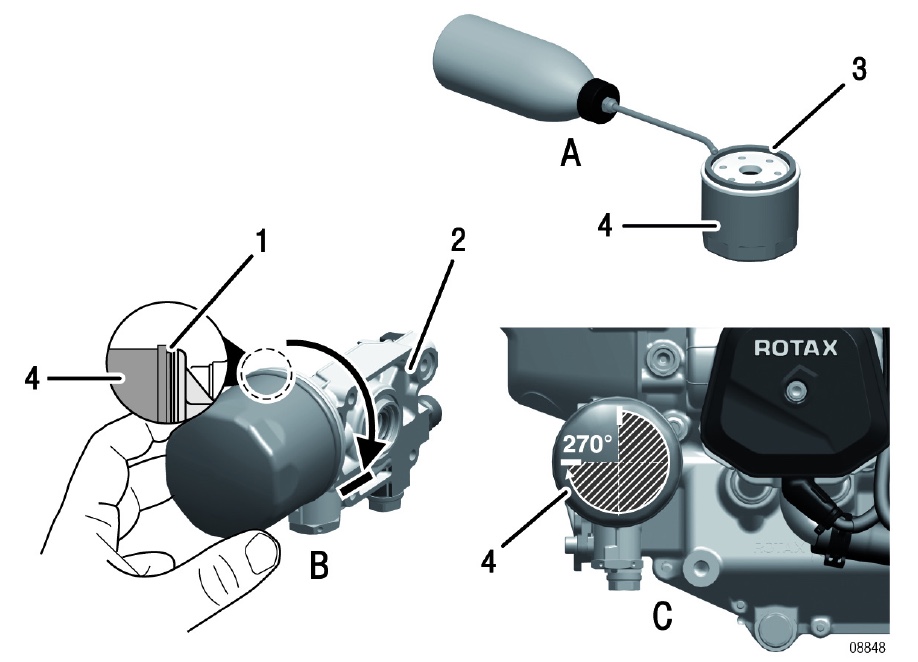

Rotax has issued a new mandatory service bulletin covering their oil filters –

Rotax has issued a new mandatory service bulletin covering their oil filters –